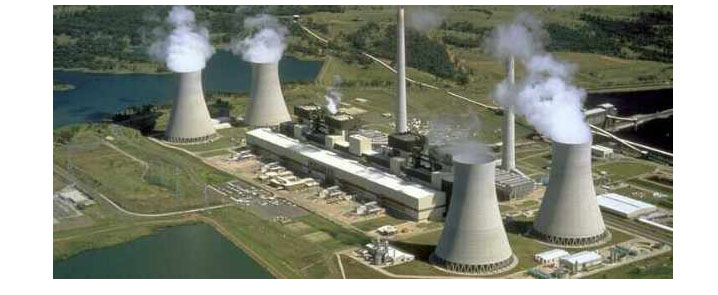

Heat Recovery & Coal / Biomass Fired Power Plant

|

| Power Plant |

To Our Customers

Certified and authorized by Chinese Govenment we, SSIT, are a leading Engineering company involved in the metallurgical & coal industry and associated power generation applications. We are committed to provide our customers with a myriad of optimized power plants. With its experience in the domestic power projects, we have at our disposal proven experience.

Our goal is to provide technically advanced and cost-effective power plant with design, equipment supply and services based on experience and expertise accumulated by executing numerous power plant projects. We try to harmonize "the human & the engineering" and also provide all the needs of the power industry. The customer's satisfaction is our goal.

Service Provided

- Feasibility studies

- Project planning

- Basic/Detail Design & Engineering

- Construction Management

- Plant Testing & Start-up

- Quality Assurance & Quality Control Services

- Procurement Services

- Plant Improvement and life extension

- Training Services for engineers and Operators

- Environmental Services

- Civil and Architectural Construction & Construction Engineering Services

- Construction Supervision Services

- Research & Development

HRSG & FBC boilers

Features & Characteristics:

- state-of-art design, research, development and manufacturing capability

- Granted ASME 'S' & 'U' stamps

- Familiarity with IBR (Indian Boiler Regulations) of the statutory authorities

Vertical Type HRSG

Design basis & concept:

- Natural circulation HRSG

- Radiant cooling furnace, flue gas pass with super-heater and evaporator are designed as water cooled tubes of membrane construction acting as fully gas tight casing

- Convective third pass holding economizer section

- Fully drainable pressure parts with bare tube construction

- Single drum all welded construction

- Integral deaerator

- Cold casing insulation

Design features:

- Meet variation in flue gas volume and temperature, prolong service time of super-heater

- With lower and optimum flue gas velocity to reduce pressure part erosion problems

- Easy maintenance and accessibility

- Compact layout and limited land occupation

- Less erection workload and period

Horizontal type HRSG:

Design basis & concept:

- Natural circulation HRSG

- Radiant first pass without any tube bundles but with water cooled tubes of membrane construction

- Loose tube between first pass and second pass

- Convective second pass with bare tube evaporator and superheater

- Convective third pass with economizer

- Single drum all welded construction

- Integral deaerator

- Cold casing insulation

Design features:

- Large vertical fast passes meet variations in flue gas volume and temperature; prolong service time of superheater; facilitate delayed combustion of unburned CO that may originate during the upset condition; cool the waste gas well below abrasive temperature to reduce pressure part abrasion problems

- Lower and optimized flue gas velocity reduce pressure part erosion problems

- Bare tube construction avoids slag deposition / dust accumulation on heat exchanger surface and allows dust to fall freely into the hopper

Fluidized Bed Combustion Boiler

Design basis & concept:

- Capability to deal with rapid load changes, short start-up times

- High reliability and availability with low maintenance down time

- High combustion and boiler efficiency

- Excellent exhaust gas quality without flue gas desulphurization

- Wide turn down ratio and excellent load following capability

- Use of various fuels like rice hush and coal etc.

Auxiliaries related to boiler:

- Boiler feed water system including feed water pump, control valves and pipings etc.

- HP & LP dosing system

- Drauglit system including F.D. fan, I.D. fan and primary air fan etc.

- Deaerator

- ESP

Steam Turbine

Awarded the National Quality Medal, our steam turbine suppliers manufacture steam turbine of various types with power output up to 60MW for small and middle sized power station, covering condensing, back pressure, extraction, mixed pressure and machinery driving etc.

Characteristic of extraction condensing steam turbine:

- Suitable for various working conditions and speeds

- Automatic adjustment of power loading

- Under extraction or pure condensation operating condition

- EDH or fully hydraulic governing system

- Compact construction

- Easy and convenient installation

- Stable and reliable service

- Suitable to drive a generator or other machinery

Generator

Steam turbine generators are 3-phase, WYE-connected, 50Hz, and totally CACW (closed air closed water) synchronous machines rated at the capacity suited for operation at the maximum capability of corresponding steam turbines.

Auxiliaries related to turbo-generator:

- Condensate water system

- Complete oil lubrication system

- Complete control and hydraulic oil system

- Turning gear

Other major systems of Power Plant

- Electrical system including transformer, MCCs, switch gear, cabling, illumination & earthing etc.

- Fuel storage & handling system including belt conveyors, crusher and screen etc.

- Ash handling system

- Plant water system including cooling water system, DM water system, potable and service water etc.

- Compressed air system

- Air conditioning and ventilation system

- Instrumentation and control system including DCS

|